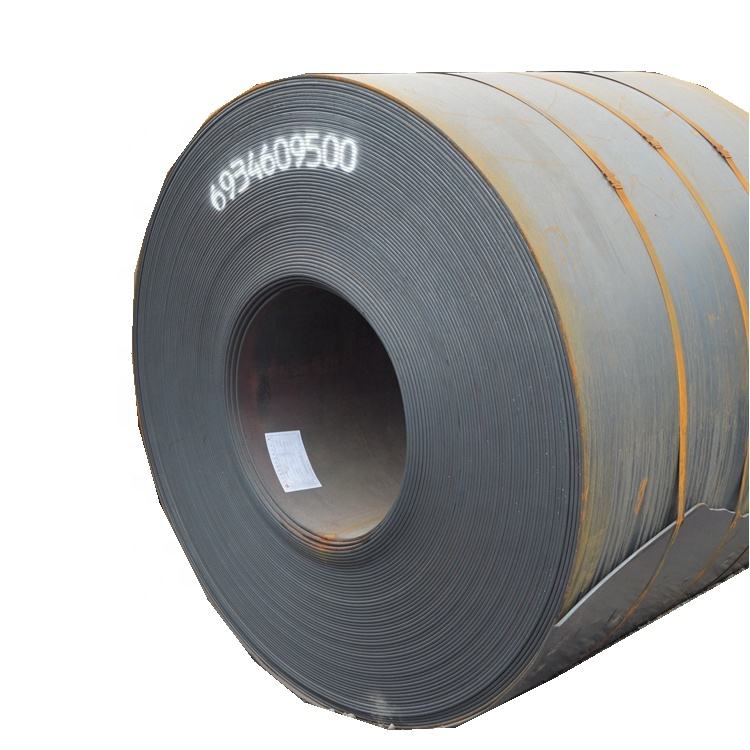

Ss400, Q235, Q345 Sphc Black Steel Carbon Coil Coil Iron Steel Metal Hr Hot Rolled Steel Coil

I-steet eshushu eqengqelekayo/ikhoyili ukusuka ekugqibezeleni intsimbi yokugqibela eshushu yokusila ngaphandle ngokusebenzisa ukupholisa kwe-laminar ukuya kwiqondo lobushushu elibekiweyo, elibandakanya ikhoyili ye-winder, ikhoyili yentsimbi emva kokupholisa, ngokweemfuno ezahlukeneyo zabasebenzisi, ngomgca wokugqibezela owahlukileyo (i-flat). , ukuqondisa, ukunqumla okanye ukusika ixesha elide, ukuhlolwa, ukulinganisa, ukupakishwa kunye nelogo, njl.) kwaye ibe yintsimbi yentsimbi, i-flat roll kunye ne-longitudinal cutting steel strip products.Ngenxa yokuba iimveliso zetsimbi ezishushu ezishushu zinamandla aphezulu, ukuqina okuhle, ukusetyenzwa ngokulula kunye nokumiliselwa okuhle kunye nezinye iipropathi ezigqwesileyo, zisetyenziswa ngokubanzi ekwakheni iinqanawa, iimoto, ibhulorho, ukwakhiwa, oomatshini, inqanawa yoxinzelelo kunye namanye amashishini okuvelisa.

| IBanga | Irenki | Ukwakheka kwemichiza(%) | ||||

| Q215 | C | Mn | Si | S | P | |

| A | 0.09~0.15 | 0.25~0,55 | ≤0.3 | ≤0.05 | ≤0.045 | |

| B | ≤0.045 | |||||

| Q235 | A | 0.14~0.22 | 0.30~0,65 | ≤0.3 | ≤0.05 | ≤0.045 |

| B | 0.12~0.20 | 0.30~0,70 | ≤0.045 | |||

| C | ≤0.18 | 0.35~0,80 | - | ≤0.04 | ≤0.04 | |

| D | ≤0.17 | ≤0.035 | ≤0.035 | |||

| Q255 | A | 0.18~0,28 | 0.40~0,70 | ≤0.3 | ≤0.05 | ≤0.045 |

| B | ≤0.045 | |||||

| Q275 | 0.28~0,38 | 0.50~0,80 | ≤0.35 | ≤0.05 | ≤0.045 | |

Intsimbi yeCarbon luhlobo oluqhelekileyo lwentsimbi eyi-alloy yentsimbi kunye nekhabhoni.Inomxholo ophezulu wekhabhoni, indawo ephantsi yokunyibilika kunye nokuqina okukhulu xa kuthelekiswa nentsimbi engenasici.

Intsimbi yeCarbon yeyona nto isetyenziswa kakhulu ubunjineli kunye nolwakhiwo lwezixhobo zokusebenza kwimizi-mveliso kwinqanaba elikhulu, kubandakanya izakhiwo zaselwandle, izityalo zamandla, uthutho, ukusetyenzwa kweekhemikhali kunye nokuveliswa kwepetroleum kunye nokusulungekiswa.

Δ Isixhobo esishushu esongwayo sifakwa kwiziko elibandayo eliqengqelekayo nasemva kokuchola kwiasidi.

Δ Zonke iiroli zokusila zisilwa kumatshini wokusila ochanekileyo one-chamfering efanelekileyo emva kokusebenza kweshifti yokuqala.

Δ Onke amashiti acholwa kwiitanki ezahlukeneyo kwaye amaphepha omisiwe kumatshini webrashi yokuqengqeleka phambi kokuba athunyelwe.

Δ La maphepha aphinda afakwe kwi-annealing emva koko athunyelwe kumatshini wokulungelelanisa kunye nokucholwa kweasidi kwaye athumele ukupakishwa ngokobukhulu kunye nomgangatho.

Δ Uhlolo lwenziwa ngokwamanqanaba ahlukeneyo.Ngamava abasebenzi abagcina ulawulo olululo lulonke lwenkqubo yangaphakathi ngokuqengqeleka, ukutsala, ukuchola, ukunyangwa kwenkunkuma njl.njl.